This is the logo for my partner’s theater company in Denver.

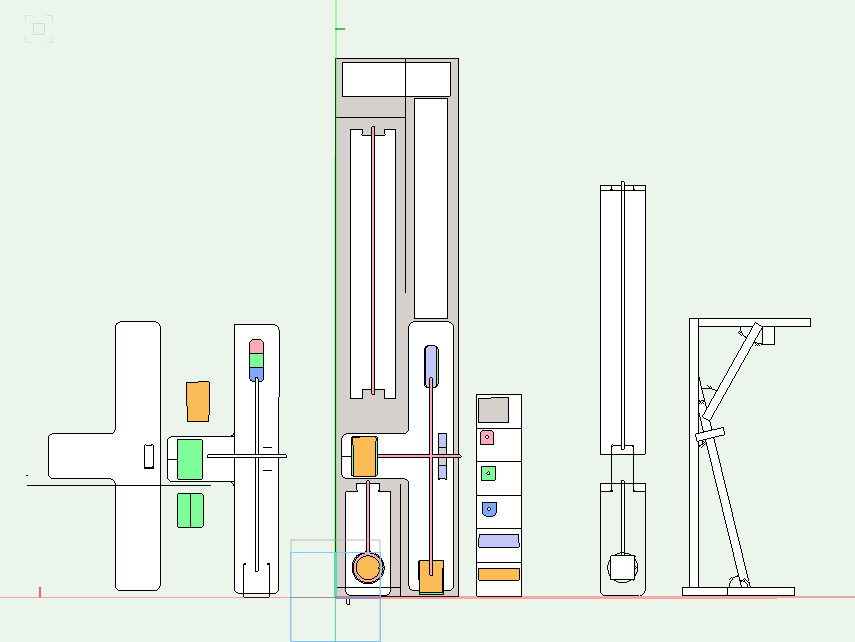

I’m hoping to make a bas-relief replica of that logo that the company can hang up at events. I imported the file into Vectorworks, then traced it and separated out layers that could be cut out at different depths with different bits.

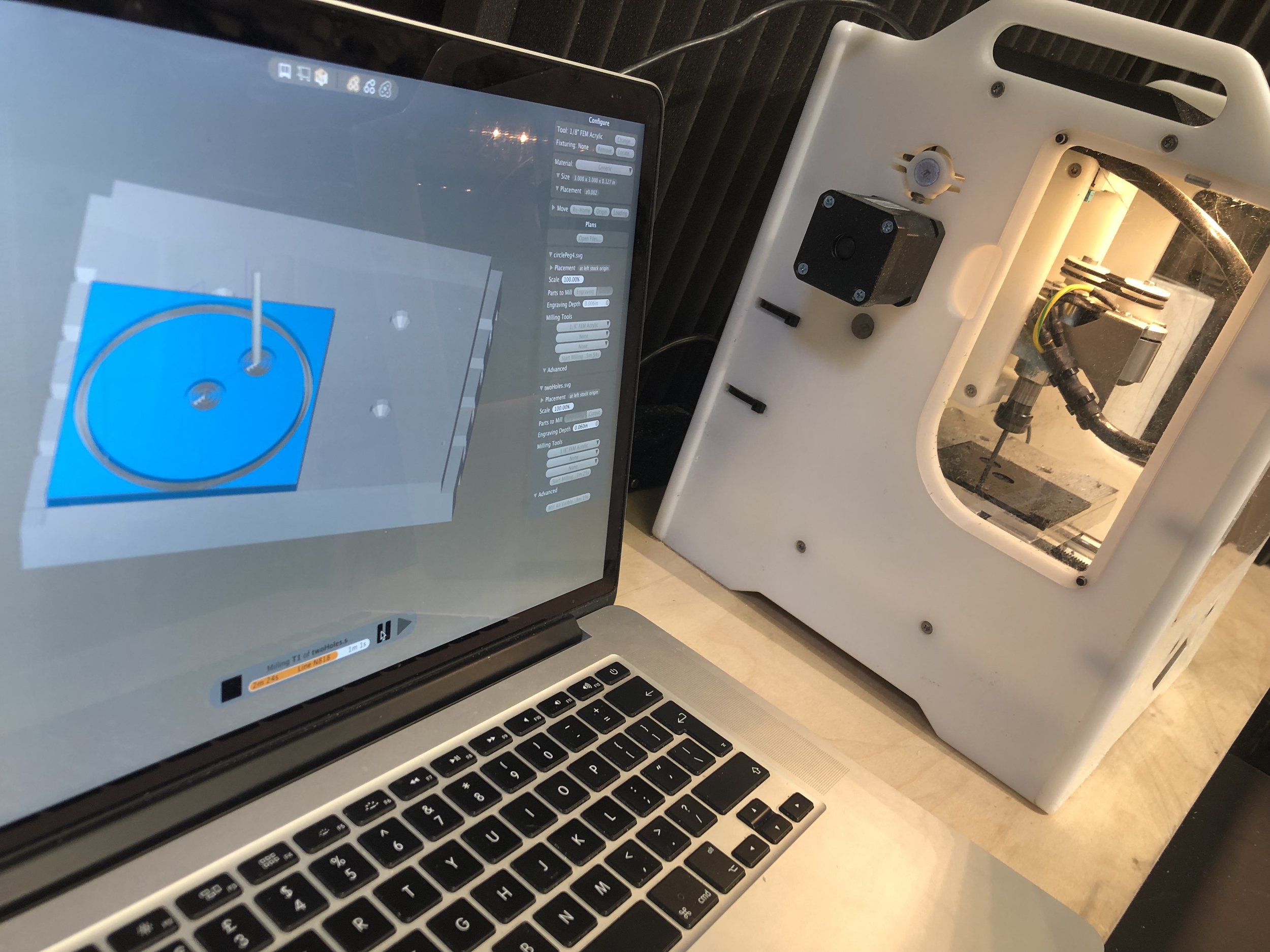

After an awfully long time on the MasterCAM machine exporting out each layer, I began the work of cutting out everything with the CNC router.

I started by cutting out the larger circle, then I used the ½” bit to pocket out the skin and hair areas at the proper depths, then used a special bit to cut out the finer lines.

When I was about one cut away from finishing, I realized I needed to make a small adjustment on the z-Axis. I paused the machine, re-zeroed, then clicked start. Nothing happened the software was stuck. I clicked “reset,” thinking that maybe that would fix it, and the mill went back to zero, plowing through much of what I had already cut.

I tried to fix it by pocketing down the large circle to below where the gouge had happened, but it left the whole thing a lot uglier than it had been before.

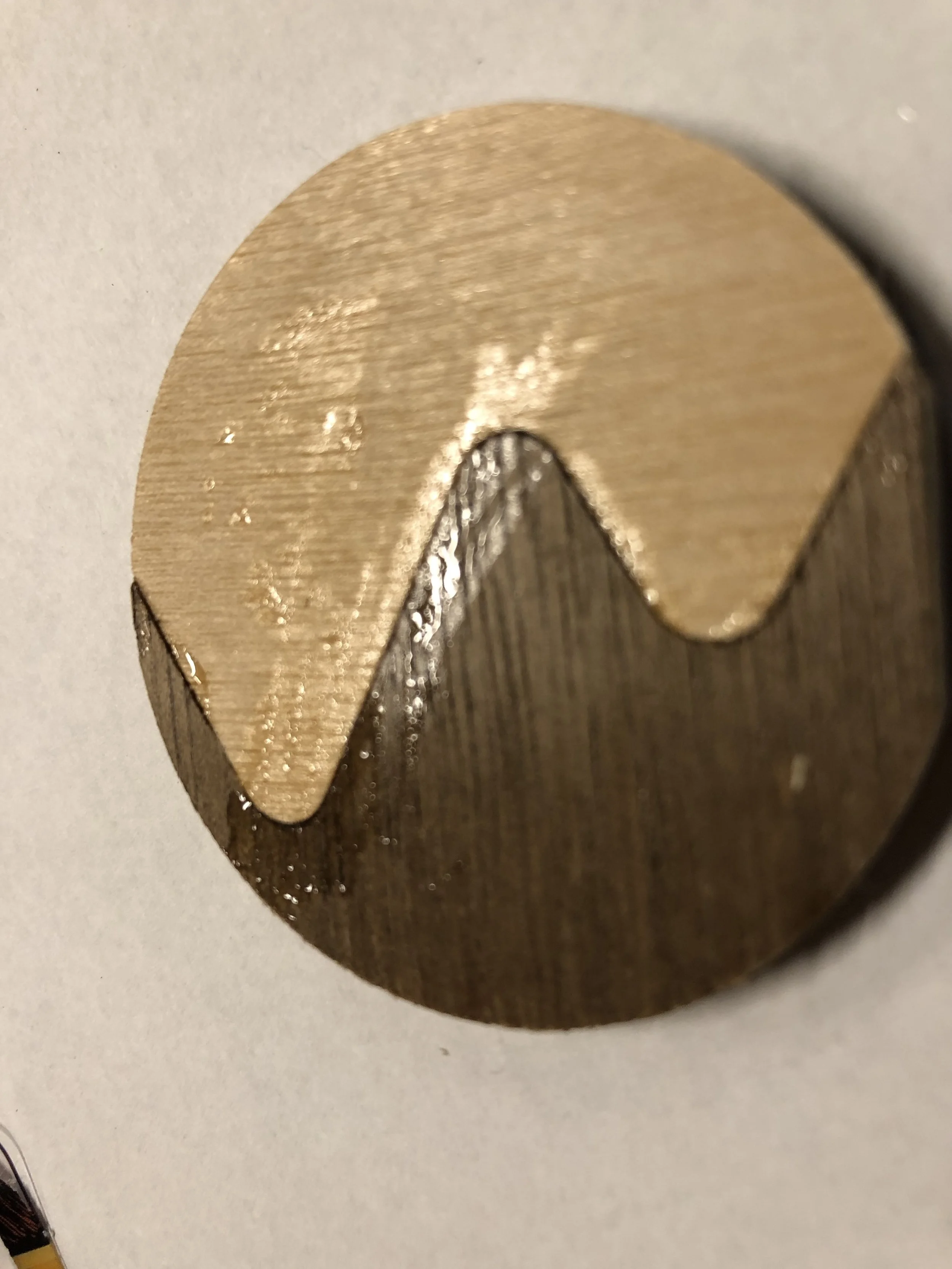

I needed to cut my losses on the big circle background. Fortunately, I still had all the pieces cut out for the sphinx itself, which is what I’ll be focusing on in class tomorrow. I sanded each piece down until they were smooth, then took some different shades of wood stain to it.

After some stain and tung oil, I have my sphinx. I think it’s looking pretty good, and I’m excited to rebuild the outer circle so that everything fits together.

Looks like everything fits! Time to glue it together and hang it up.

Puppy included for scale.