I wanted to solve a problem with this project. My problem looked like this.

This is a camera mount that I’ve been using as a pencil-tester for hand-drawn animation. While it might be a good example of valuing function over form, I’m a little surprised that the whole thing hasn’t fallen over yet. So I set out to make a new one.

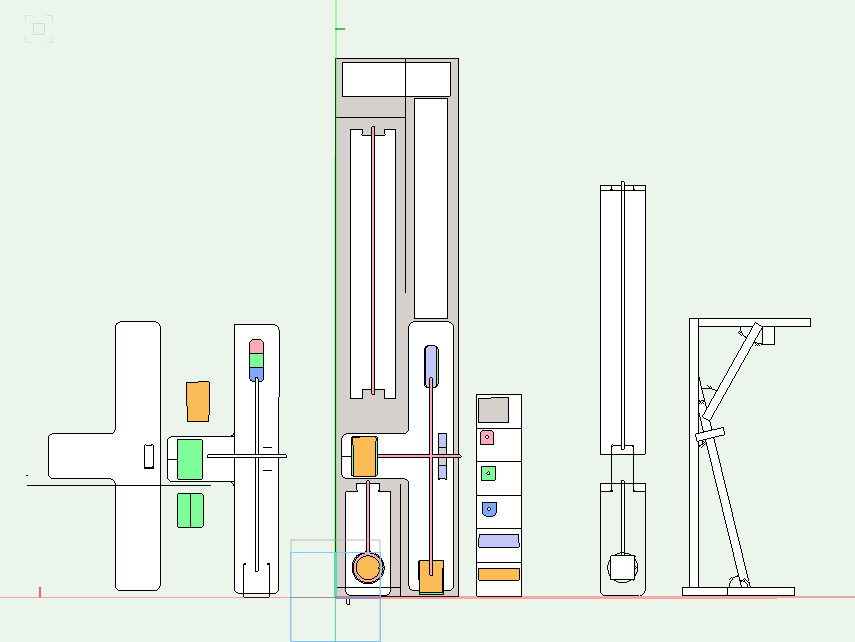

I know that the purpose of this project was to keep it simple, but this is something I wanted to use for an upcoming midterm, so I needed to go a little farther on this one.

I screwed down a 4’x11” piece of plywood, and I ran a rough trace of my contours just to be sure that everything would fit.

Well, that’s interesting. The surface is uneven in a way that the bit was cutting into the wood at the top end, but not on the bottom. That wasn’t totally unexpected, though, given how big the piece was. Precision in the z-axis wasn’t the most important thing for me on this project, so I just went ahead.

I cut the whole thing with an 8-inch bit, so it took a while. Sorry if anyone else wanted to use the CNC on Sunday. I cut out the pockets first, making sure that elements were fitting properly as I went

Once the pockets were dug, I screwed in each piece and cut out the contours. By the end of it, I didn’t have a whole lot of scrap left, but I did have a pretty nice-looking camera mount.

I had wanted to add in some sliders and knobs to control a lamp that I had placed in the top, so I took some of the elements that I had been using to make pockets in Vectorworks and modeled wooden plates from them. I then made some smaller plates for knobs and sliders on the Bantam.

And ultimately, now I have an animation stand on my desk. It’s still a bit of a rough draft – the interfaces probably need to be re-soldered and the plates don’t exactly fit in (I think I might make a refined version of the base for my next CNC project), but overall this was a fun process and I’m excited to be able to make some more cool stuff with the CNC.